|

Description |

| Ball Grinder is widely used in mining, building materials and chemistry industries.

2. According to the grinding way, Ball Grinder can be divided into dry and wet types. According to ways of discharge, the Ball Grinder can be divided into lattice and overflow types or center-discharge and side-discharge types. In accordance with the different kinds of support, it can be divided into Bearing Grinder and Bushing Grinder. In accordance with the different kinds of transmission, it can be divided into edge and center types. The grinders with the diameter above 3m allocate jacking devices for easy maintenance. So the dynamical pressure bearing and the static pressure bearing can operate stable. |

| |

|

End Bottoms |

|

|

Description |

|

| The most frequently used tool on a vertical milling machine is the end mill. End mills are made in either a right-hand or a left-hand cut. Identification is made by viewing the cutter from the cutting end. A right-hand cutter rotates counterclockwise. The helix of the flutes can also be left or right hand; a right-hand helix flute angles downward to the right when viewed from the side. An illustration of the cutting end of a four flute end mill, which is an example of a right-hand cut, right-hand helix end mill is shown below.

The end teeth of an end mill can vary, depending on the cutting to be performed. Two flute end mills are center cutting, which means they can make their own starting hole. This is called plunge cutting. Four flute end mills may have either center cutting teeth or a gashed or center drilled end. End mills with center drilled or gashed ends cannot be used to plunge cut their own starting holes. These end mills only cut with the teeth on their periphery. End mills can be single end or double end (see table). Double end type end mills are usually more economical because of the savings in tool material in their production. |

|

| |

| |

|

|

Bearing Housing |

|

|

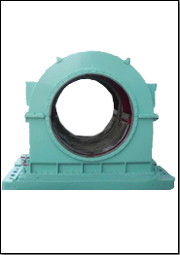

Description |

|

| We are instrumental in providing our clients with a comprehensive range of Bearing Housing for ball mill. Our range is designed at par with international quality standards & norms using high grade castings. Apart from this, our range is widely used for both light and heavy duty applications. Our range of bearing housing is available in different sizes & dimensions, and can be customized as per the specifications detailed by the clients. |

|

| |

| |

|

Girth Gears |

|

|

Description |

|

Leveraging on well equipped infrastructure facilities and dedicated staff members, we are able to manufacture, supply and retail an exclusive range of Ball Mill Girth Gears. We have fabricated these gears by utilizing the premium quality materials and sophisticated technology tools. Due to their unmatched quality, sturdiness, reliability, abrasive resistance and excellent strength, these gears are demanded all over the world.

Features:

Precisely engineered

Accurate dimensions

Rust proof |

|

| |

| |

Pinin & Pininshaft |

|

|

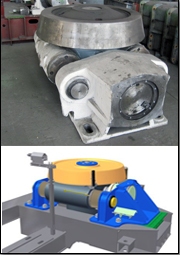

Description |

|

| Pinion shafts are present in most gear train assemblies. The pinion shaft transfers the input of drive shafts (commonly known as cranks) to generate the work for which gear trains are designed. Pinion gears transfer the drive motion to linear gear assemblies or to 90° bevel gear or miter gear assemblies.High quality pinion shafts are typically single-piece assemblies manufactured from one piece of steel stock.

Most gear train assemblies transfer rotational mechanical inputs into an output of velocity or torque. Most input drives are supplied by drive shaft or crank mechanisms. Applications of these pinion shafts working includes drive shafts on automobiles and the drive mechanism on a fishing reel. The pinion shaft, therefore, forms the first stage of the gear train. |

|

| |

Diafarm |

|

|

Description |

|

| |

|

| |

|

Shell Liner |

|

|

Description |

|

Advantages of Shell Mill Liners:

Optimum lifting action of the balls.

Optimum expansion of the ball charge.

Minimize the dead zone of the ball charge.

Significant reduction of the wear rates of the ball and the liners.

Minimum operating cost due to longer lifetime and no breakage of the liner plates. |

|

| |